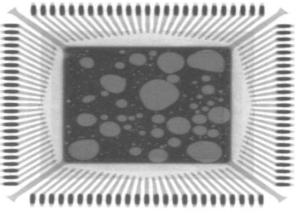

High performance electronics and power devices are driving higher power densities. As a result, void free solder connections are increasingly a necessity in order to comply with today’s reliability standards. Voids in solder joints can lead to many undesirable issues such as

- Device overheating

- Reduced electrical performance

- Reduced RF performance for high-frequency applications

- Lower overall reliability

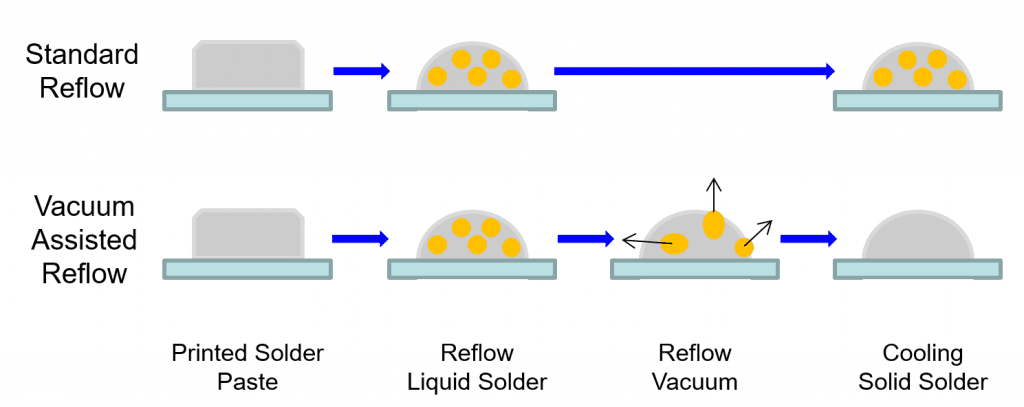

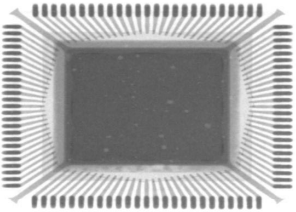

Voids can be effectively removed with vacuum assisted reflow.

Trapped gas bubbles increase in size as pressure is reduced.

Larger bubbles combine with other bubbles and ultimately collide with the edge of liquid solder to escape.

Larger bubbles are accelerated by stronger buoyancy forces making them more likely to escape.